The lining material of the molten aluminum launder and trough is made of high-density molten silicon sintered, and the anti-aluminum infiltration material is added to improve the service life of the launder. At the same time, it has a small thermal expansion coefficient, better thermal shock resistance, and rapid cold and rapid heat resistance. Microporous thermal insulation wool is used as the thermal insulation material inside the ceramic launder, which has good thermal insulation performance and effectively reduces heat loss.

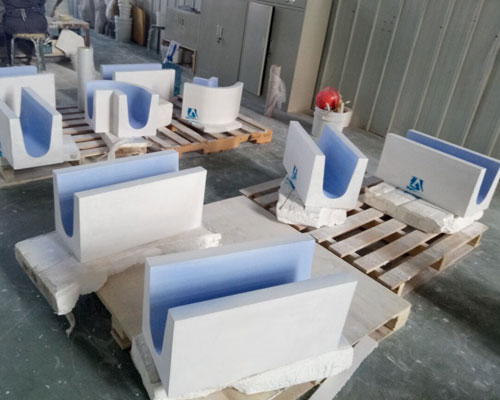

AdTech can design, produce and sell different sizes and special-shaped molten aluminum launder and trough according to customer needs. Our company adopts advanced production technology of integrally formed runner lining: greatly improving the erosion resistance and erosion resistance of runner lining. Effectively extend the service life of the runner lining. Used with our company’s boron nitride coating, it has excellent non-sticking effect on aluminum, and the inner lining can be made and supplied independently according to the needs.

The integral launder equipment produced by AdTech is installed between the furnace and the casting machine. It has dual functions: conveying and heat preservation. It is mainly used for transportation of aluminum liquid between aluminum alloy precision casting furnaces, purification furnaces, casting platforms, degassing outside the furnace, and filtering for aviation and transportation.

Molten Aluminum Launder and Trough Advantages

1. Small thermal expansion coefficient, good thermal shock resistance, good insulation performance, and reduce energy consumption;

2. Scientific and reasonable design, easy to transport and install;

3. Good surface anti-wetting property, resistance to aluminum liquid erosion, and corrosion.