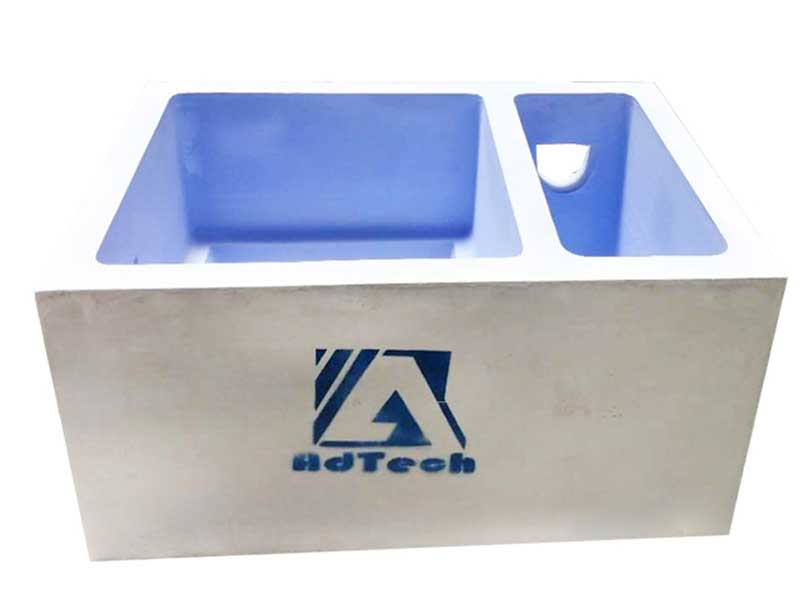

Cff Filter Box is used for high precision aluminum melt purification, which is used in conjunction with Degassing Unit.

Its lining has an ultra-long life furnace body, and its material adopts a new high-silicon melting manufacturing technology.

Built-in Ceramic Foam Filter to filter inclusions and tiny particles in aluminum liquid.

Cff Filter Box replaces the expensive ceramic tube filter equipment and ordinary plate filter equipment products.

For the production of aluminum products, micron-level impurities are effectively filtered and blocked to meet customer needs.

Such as: rail transportation alloys, electronic alloys, micron aluminum foil wool, PS board base for printing, can making materials and other products.

Cff Filter Box parts include

Mechanical transmission, hydraulic transmission

Box cover

Heating system

Electrical control system

Cff Filter Box Usage

1. Used for filtering and purifying aluminum and aluminum melt, carrying filter plate, filtering inclusions and tiny particles in aluminum liquid, especially suitable for production of high-purity high-precision aluminum and aluminum alloy

2. It has the advantages of high temperature resistance, oxidation resistance, corrosion resistance, fast temperature rise, long life and strong acid resistance.

Cff Filter Box Advantages

1. Silicon carbon rod is made of high purity silicon carbide.

2. It can be used continuously for 2200 hours at normal temperature of 1450 ℃.

3. High temperature resistance, oxidation resistance, corrosion resistance, fast temperature rise, long life, strong acid resistance.

4. The shell of the equipment is made of welded steel plate, and adopts advanced rust removal technology and corrosion-resistant coating.

5. Lifting and rotating box cover, small size, high precision, complete synchronization, good self-locking performance, good stability and stable structure.

6. The high-silicon molten material is lined with non-stick aluminum, which has high corrosion resistance and oxidation resistance and long service life.

1. Used for filtering and purifying aluminum and aluminum melt, carrying filter plate, filtering inclusions and tiny particles in aluminum liquid, especially suitable for production of high-purity high-precision aluminum and aluminum alloy

2. It has the advantages of high temperature resistance, oxidation resistance, corrosion resistance, fast temperature rise, long life and strong acid resistance.

Equipment Specifications

|

Specification |

Filtering mode |

lifting method |

The lining |

Heating cover |

|---|---|---|---|---|

|

15in |

Hydraulic rotation/ mechanical rotation/ flip open |

Can be produced separately |

||

|

17in |

Primary filtration / two stage filtration |

Hydraulic rotation/ mechanical rotation/ flip open |

Can be produced separately |

Can be produced separately |

|

20in |

Primary filtration / two stage filtration |

Hydraulic rotation/ mechanical rotation/ flip open |

Can be produced separately |

Can be produced separately |

|

23in |

Primary filtration/two stage filtration |

Hydraulic rotation/ mechanical rotation/ flip open |

Can be produced separately |

Can be produced separately |

|

26in |

Primary filtration/two stage filtration |

Hydraulic rotation/ mechanical rotation/ flip open |

Can be produced separately |

Can be produced separately |

The lining material of the filter box is not sticky, and the effect of applying Boron Nitride is better.

Packing and Delivery

Instructions for use

1. Combine with the foundation drawing of the factory to install the filter box.

2. Ensure that the overall filter box lining is clean to avoid damage and cracks.

3. After the filter box is installed in place, the inner lining is preheated evenly by electric baking and gas baking.

Note: There should be no open flame contacting the lining, and it should be implemented according to the standard of the baking curve. The maximum temperature should be controlled within 850 ℃ to remove the adsorbed crystal water and use it safely and efficiently.

One-Stop Shopping for Aluminium Melting Materials