The purification effect of aluminum alloy melt is mainly determined by dissolved hydrogen and non-metallic inclusions. Hydrogen is the most important factor leading to the formation of porosity; non-metallic inclusions can become the heterogeneous core of pores and promote the formation of porosity. Due to the “uncertainty” of its behavior, the porosity changes greatly, which seriously affects the reliability of castings.

It is generally believed that the formation of porosity is the result of the combined effect of solidification shrinkage and hydrogen precipitation. There are many factors that affect porosity, but many researchers believe that hydrogen content is the most decisive among all related factors.

The research results show that the porosity is inversely proportional to the cooling rate and directly proportional to the initial hydrogen content. When the cooling rate is greater than 5, the concentration of main mountain hydrogen is determined. The porosity depends only on the hydrogen content and has nothing to do with the temperature index. Corresponding to a certain cooling rate, there is a critical hydrogen content. At this concentration, a certain residual volume fraction of pores is formed, and the critical hydrogen content increases with the cooling rate. However, hydrogen is not an independent factor. When hydrogen is used as an interactive factor, its influence on porosity strongly depends on other factors. Inclusions (especially oxide inclusions) are a very typical example. Even the presence of a small amount of inclusions can significantly reduce the critical hydrogen concentration value that forms pores. On the other hand, in the case of “no inclusions” (or extremely low inclusion content), the critical hydrogen concentration value for forming pores can be as high as 0.3 mL of hydrogen per 100 g of aluminum.

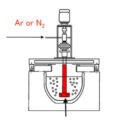

AdTech offers online degassing system and CFF filtering unit for removing hydrogen and impurities in molten aluminum, it can improve the purification effect of aluminum.