The bubble floatation method is divided into single-pipe air blowing method, multi-hole air blowing method, fixed blowing method and rotary blowing method.

The single-tube air blowing method is an earlier air blowing refining method. Because of its simple equipment and simple operation, it is usually adopted by micro-small aluminum alloy casting enterprises. However, in this method, due to the large inner diameter of the blow pipe, the bubbles generated in the aluminum liquid are large, which makes the aluminum liquid easy to splash and has poor hydrogen removal efficiency. In order to improve the refining effect, the micro-hole blow head refining process was developed on the basis of a single tube, which greatly increased the gas-liquid contact area, and the reduction of the bubble floating speed increased the gas-liquid contact time.

The most typical fixed injection method is the MINT method developed by the United Aluminum Corporation of America, which uses the vortex generated by the flow of the alloy liquid through the cone and the small bubbles generated by the relative impact of the high-pressure inert gas to remove hydrogen. The full flow of the aluminum liquid extends the gas The liquid contact time can achieve a degassing rate of about 50%.

The effect of the rotary injection refining process on the gas content of 7075 aluminum alloy. The results show that among the various influencing factors of rotary injection, the rotor speed has the largest effect, followed by the gas flow rate and the standing time, and the refining time has the smallest effect. The purification and degassing rate of traditional C2Cl6 is 34.5%, while the degassing capacity of the rotary injection method is up to 70%. The two are mixed and refined. The outgassing rate is 78%, and the mechanical properties of the alloy after refining under the three processes are correspondingly increased.

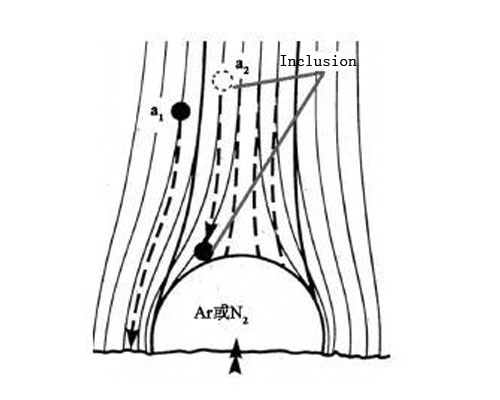

In order to solve the shortcoming that the impurity-containing bubbles rising to the surface of the melt are re-entangled in the melt due to the stirring effect of the rotary injection method, the advantages of small bubbles generated by the rotary injection are fully utilized, and the stator and rotor are designed to rotate and shear the bubbles. The principle-processed rotating pulse jet aluminum alloy liquid purification device, and water simulation proves that it can produce uniform and small bubbles, and the degree of stirring is greatly reduced compared with the rotating method. The constant pressure continuous air intake method of conventional rotary injection purification is changed to pulse air intake, which makes the generated bubbles smaller and improves the degassing and purification ability.

The research on the rotating jet purification method mainly involves the design and manufacture of the nozzle, and the shape and size of the bubble formed. The typical foreign rotary injection processes mainly include the SNIF method of Union Carbide Corporation of the United States and the PAL method of Petrotech Company, the ALPUR method of French Pisigne Company, and the RDU method of United Aluminum Corporation of the United Kingdom. Their nozzle structure and purification process have their own characteristics, but they all have the disadvantages of complex structure and difficult processing, and in addition to ALPUR, they can cause serious boiling of the liquid surface.

It can be seen that, based on the nozzle structure design and bubble parameters of the bubble floatation method, the research on the degassing efficiency of aluminum liquid refining has been in-depth, and it has been able to meet the production needs. However, in actual production, in order to reduce the production cost, only the gas content is required to meet the product requirements, which requires a good control of the relationship between melt suction and degassing.