Electrolytic aluminum liquid purification is important for aluminum factory. Aluminum foundries use more stringent purification processes to ensure the purity of the aluminum melt. In production, after six times of purification, slag discharge and degassing, to ensure the effect of melt purification.

The temperature of the electrolytic aluminum solution is as high as 950°C, which contains metal impurities such as silicon, iron, sodium, calcium, phosphorus, boron, titanium, vanadium, and zinc, as well as non-metallic inclusions such as alumina, aluminum, fluoride, carbon, aluminum carbide and aluminum nitride. When the temperature of the electrolytic aluminum liquid in the ladle is 760℃-840℃, the gas content is high, and the hydrogen content can reach 0.6ml (100gAl)-1.29ml/(100gAl). The presence of gas in the melt and various metallic and non-metallic inclusions can cause structural defects in the ingot, which in turn affects the structural properties of processed products. Therefore, the aluminum alloy must be melted when producing aluminum alloy slabs with electrolytic aluminum liquid components.

Electrolytic Aluminum Liquid Purification

First Purification

After the melt pretreatment in the smelting furnace, the electrolytic aluminum liquid is injected into the smelting furnace, and the powdery slag remover is sprayed on the surface of the melt according to 0.1%-0.2% of the melt weight, and the electromagnetic stirring is carried out for 12 minutes and then left for 20 minutes. Remove scum on the surface of molten aluminum. Through melt pretreatment, the aluminum oxide slag brought from the electrolytic cell can be removed initially, and the furnace wall slag can be reduced.

Second Purification

After slagging and degassing refining in the smelting furnace, after the charge is completely melted and the temperature of the aluminum liquid reaches 740~760 degrees, electromagnetic stirring for 10-15 minutes, so that the temperature of the upper and lower surfaces of the aluminum liquid and the chemical composition of the alloy in the furnace are uniform, and the melt is stripped again After the surface scum is sampled and analyzed, after the composition is qualified, the chloride salt refining agent is added for refining, the refining agent is 0.2%-0.3% of the melt weight, and the melt is again electromagnetically stirred for 12-24 minutes.

Through electromagnetic stirring, the temperature of the upper and lower surfaces of the molten aluminum and the chemical composition of the alloy in the furnace are uniform. At the same time, the melt can be moved under the action of electromagnetic stirring force and can fully contact with the flux, thereby improving the refining effect. After the refining is completed, evenly sprinkle a layer of slag remover on the surface of the melt. After standing for 20 minutes, remove the scum on the surface of the melt. Since the chloride salt refining agent reacts with the aluminum melt to produce gaseous AlCl3 (boiling point is 183℃), which is insoluble in the aluminum liquid and can play a role in hydrogen removal refining. Therefore, the slag refining in the smelting furnace also removes part of the hydrogen. Through the secondary electrolytic aluminum liquid purification, the purpose of the second deslagging and the first degassing is achieved.

Third Purification

Inert gas purging and refining in the static furnace in the static furnace, nitrogen (argon for high magnesium alloy) is evenly blown into the melt through the ventilated bricks at the bottom of the furnace to refine the melt, and the amount of nitrogen added is 45 per ventilated brick L/min, refining time is 30 minutes. After the refining is completed, the slag remover is sprinkled at 0.15% of the weight of the melt, and it is allowed to stand for 20 minutes, and then the surface scum is removed. Purging and refining with inert gas can achieve both slag removal and dehydrogenation: the use of gas partial pressure to achieve dehydrogenation, and adsorption to remove slag inclusions.

Fourth Purification

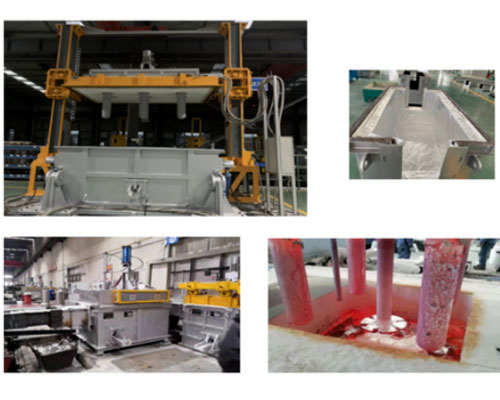

The on-line degassing refining adopts a rotary degassing system for online processing. The refining gas is nitrogen (or gas) with a purity of not less than 99.99%; the melt temperature is 720-740℃; and the rotor speed is 180-230 revolutions/min. The online degassing device can produce two aspects of electrolytic aluminum liquid purification effect:

(1) Removal of hydrogen: the hydrogen is absorbed into the bubble by the hydrogen partial pressure difference inside and outside the bubble and brought out of the aluminum alloy melt surface to remove hydrogen.

(2) Deslagging: The device captures the slag by the scattered air bubbles and brings the slag to the surface of the melt to remove it.

Fifth Purification

On-line filtration and deslagging production line adopts CFF two-stage ceramic foam filter plate for filtration, and the CFF filter box is equipped with 2 sets of parallel filter plates, and the processing flow rate is 55t/h. The filter plate is a double layer 30/50ppi composite foam ceramic filter plate, the porosity of the upper filter plate is 30ppi, and the porosity of the bottom filter plate is 50ppi. The upper filter plate (30p) with less porosity intercepts larger-sized impurities and the lower porosity More filter plates (50ppi) further improve the filtering effect, and slag inclusions are isolated on the upper part of the filter plate. The CFF ceramic foam filter device can effectively remove slag inclusions with a diameter greater than 20 μm, and the filtration efficiency can reach 75%.

Sixth Purification

Filter and remove slag before ingot casting. The front end of the casting port is filtered and removed with a 100 mesh glass fiber filter. A special metal distribution filter bag is used in the crystallizer to carry out the final slag removal and purification treatment to remove the aluminum melt in the distribution trough and Aluminum oxide film produced when entering the crystallizer. After the above six electrolytic aluminum liquid purification processes, the degassing and slagging effect is obvious, the hydrogen content is less than 0.15m100gA1), the sample is taken for metallographic low-power test, and no slag inclusion is found.