LHC Casting System is advanced molten aluminum casting technology, uses electrolytic raw aluminum liquid to directly produce aluminum alloy slab ingots. The quality of aluminum and aluminum alloy ingots is closely related to the quality of final processed products and the yield rate. Defects that are not easy to detect or detect during the smelting and casting process will be manifested in the subsequent processing procedures, but the processing procedures cannot eliminate these defects. Therefore, the quality of aluminum alloy slabs directly affects the quality of the hot rolling process and the subsequent cold rolling products. In order to provide high-precision aluminum strips with large specifications and high-quality blanks for aluminum processing enterprises, an electrolytic aluminum plant introduced advanced automatic low-level combined forming device casting technology(LHC Casting System), which can produce 2-5 slabs at the same time.

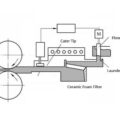

According to the requirements of the chemical composition of the alloy, the raw aluminum liquid for electrolysis, the aluminum ingot for remelting, the returned waste and the intermediate alloy are used for batching, and then smelted in the melting furnace. After degassing and filtering, refining, stirring, slagging and sampling analysis are adjusted and the composition is qualified, the aluminum liquid is transferred to the static furnace for degassing and refining in the furnace and the temperature is kept standing. Then, the aluminum-titanium-boron wire fine particle refining agent is continuously added in the launder to perform online fine-graining. The on-line degassing is carried out by the rotating degassing device, and the CFF two-stage foam ceramic filter device is used for on-line filtering and slag removal. The treated molten aluminum flows into the crystallizer of the slab casting equipment. The ingot is produced according to the fully automatic casting process, and the ingot is sawed on the slab sawing machine, and the ingot is packaged and stored after passing the inspection.

LHC Casting System Features

Compared with the traditional production of slabs using aluminum ingots for remelting, it not only saves the remelting process, saves energy, but also reduces metal burnout, reduces environmental pollution, and reduces production costs.

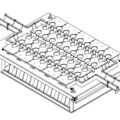

Using low-level combined mold automatic casting technology, the metal level is much lower than the metal level in the traditional DC casting mold. The height of the liquid level is between 35-65mm, and the mold is lined with a graphite ring on the inner wall of the traditional DC casting finalizer. The graphite ring adopts continuous penetrating lubrication or greased before casting to smooth the surface of the ingot.

Low metal level conditions and smooth surface casting of graphite ring, as well as high-efficiency cooling water control, make LHC more compact than the ingot produced by traditional DC casting technology, with smooth surface, and reduced coarse-grained layer and segregation zone (shell zone) Thin, reduce the warpage of the bottom of the ingot. Therefore, the milling amount can be reduced by more than 50%, and the hot-rolling trimming can be reduced by more than 15%.