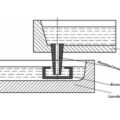

Tropical defect in continuous casting is that the liquid metal aluminum in a certain part of the casting and rolling area, only completes the crystallization process, but is not affected by the roll casting, and is brought out by the casting roll in the solidification state.

Tropical Defect in Continuous Casting Causes

- When the temperature of the liquid is higher than the temperature of the molten metal in the hot rolling zone, the temperature of the molten liquid in the hot rolling zone is higher than that in the hot rolling zone.

- When the liquid level of the front box is low, the static pressure is small, so that the liquid metal in the casting and rolling area is insufficient, resulting in hot strip; C. if the casting speed is too fast, the liquid metal will be brought out by the casting roller before the local area in the casting rolling area is completely solidified, forming a hot strip.

- Improper adjustment of graphite spraying or flame baking roller.

- The caster tip and nozzle was blocked locally, resulting in insufficient liquid metal supply in the casting and rolling area

- When water vapor enters into the casting area, it will evaporate into vapor, which hinders the continuity of liquid metal supply and produces hot strip.

Elimination Method

It is necessary to carefully observe the appearance of the hot strip, judge the cause, and adjust the corresponding process parameters according to the causes.

For the first four reasons, the amount of graphite spraying or the flame of the fire baking roller should be adjusted to reduce the casting speed, reduce the melting temperature of the front box and improve the liquid level of the front box. For the fourth reason, the melt temperature of the tundish should be increased, the slag should be broken off, and a thin steel bar (or saw blade) should be inserted into the nozzle cavity to remove the blockage.

The fifth reason is that the hot strip is periodic, and always appears in the same position of the casting roll. At this time, only stop the machine to change the roller and re erect the plate for production.