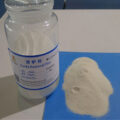

Fluxes for Melting Aluminum is an important method to purify aluminum melt. At present, there are many kinds of fluxes developed and used at home and abroad. In addition to the fluxes with the main purpose of removing gas and impurities, there are also some other fluxes, such as covering flux, slag cleaning agent, etc. According to the purpose of purification, aluminum melt purifiers can be divided into three types: gas purifier, impurity removing flux and purifying flux.

Fluxes for Melting Aluminum

Fluxes for Melting Aluminum

Gas purifier purification is to inject gas into aluminum melt or add substances that can produce purified gas. Hydrogen is diffused into the bubble by using the partial pressure difference between aluminum melt and bubble. At the same time, the bubble catches the inclusion scum in the process of floating, so as to achieve the purpose of hydrogen removal. The main Fluxes for Melting Aluminum is hydrogen removal. At the same time, because of the interaction between impurities in the melt and hydrogen, the process of hydrogen removal is accompanied by impurity removal.

The purification effect of gas purifier is based on the theory of bubble floating. According to the activity of gas purifier, it can be divided into three categories: inert gas, active gas and oxidizing gas.

(1) Affective gases refer to gases that do not react with aluminum melt and dissolved hydrogen, and are insoluble in aluminum, mainly including AR, N2, He, etc. they are non-toxic, tasteless, pollution-free, and do not need waste gas treatment facilities. They play the role of physical adsorption and hydrogen removal on aluminum melt. Recent studies have shown that physical dehydrogenation and chemical hydrogen fixation can be carried out simultaneously by using the combination of emotional gases and rare earth elements. At the same time, the movement of argon bubbles in molten aluminum can accelerate the diffusion of rare earth in molten aluminum, increase the chance of rare earth and hydrogen contacting each other, and reduce the dissolved hydrogen content in alloy rapidly.

(2) Active gas mainly refers to Cl2, in addition to ZnCl2 and other chloride or chloride gas produced in the purification process. Active gas has both physical and chemical hydrogen removal effects on aluminum melt. However, it is harmful to human body, pollutes environment, easy to corrode equipment and heating elements, and easy to make the crystal structure of alloy ingot coarse. Therefore, although Cl2 and CCl4 are used as fluxes, the purification effect is excellent. In order to avoid public hazards, people mostly use inert gas.

(3) Oxidizing gas refers to the gas generated by the decomposition of flux or reaction with aluminum melt under the action of high temperature. For example, the flux with NaNO3 + C as the main body reacts to produce n2co2. In the process of purification, no, NO2, CO and HF gases which can oxidize aluminum melt violently are generated. The non-toxic flux is also toxic in fact, so the non-toxic flux needs further research and development.