Degassing Aluminum Casting is a new technology of online purification treatment outside the furnace. It is composed of degassing equipment and filtering equipment. The effect of degassing and impurity removal is very good. AdTech degassing system and CFF filtering equipment are best for online aluminum melt purification.

Degassing Aluminum Casting

Degassing Aluminum Casting

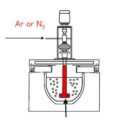

SNI method: SNI method is the abbreviation of the rotating nozzle inert gas floating method. SNF unit is a new technology developed in the 1970s, which has been widely used in the world. In this method, there is no filtering device, and the gas passes through the rotor of the nozzle to form dispersed fine bubbles. At the same time, with the melt stirred by the rotor, the bubbles are evenly dispersed into the whole melt, resulting in the purification effect of exhaust and slag removal. There are many kinds of gases used for refining. Practice shows that when nitrogen is used as the main refining gas, a large number of black-brown inclusions (an mgn2) are easily produced in the treated metal. When argon is used as refining gas, there is no black-brown inclusion in the ingot. Generally, snif device should not be used under the condition of frequent alloy change.

Alpur method: this method also uses the rotating nozzle to spray the refined gas into the melt in the form of microbubbles. But different from the nozzle of snif method, it can stir the melt into the nozzle and contact with bubbles at the same time, which improves the purification effect.

MNT process: MNT process is an external treatment device invented by Alcoa in 1982. The system consists of two parts: the degassing unit and the filtering unit. The metal capacity of the degas reaction chamber is about 800kg, and the high-pressure fixed nozzle is adopted, and the filter is made of a foam ceramic filter plate. The purification gas is argon, and a small amount of chlorine can also be added.