Molten aluminium Filtration filtration mechanism

Sieving

Like a sieve, it prevents the inclusion of particles and their agglomerates whose size is larger than the pore size of the filter surface.

Cake filter

After sieving, many inclusions larger than the ceramic foam filter hole are captured at the inlet of the filter.

As the number of captured inclusions increases, a “filter cake” composed of large inclusions is formed on the surface of the inlet end of the filter. The “filter cake” makes the liquid thinner, so that the inclusions smaller than the pore size of the filter are also partially captured on the “filter cake”.

Deep bed filtration

Inside the ceramic foam filter, the path the melt flows through is tortuous, and there is even cross-flow reversal in a small local area.

This has two main functions of Molten Aluminium Filtration

1. It can greatly increase the probability of inclusion particles contacting the filter

2. Speed up the flow rate and flow direction change of the melt, so that the small inclusions in the melt can be caught in a corner after being collided.

Installation of Ceramic Foam Filter Molten Aluminium Filtration

The filtration efficiency of the foam ceramic board is closely related to its correct installation and use. At the same time, the conventional and necessary measures taken to reduce the occurrence of inclusions during the smelting, furnace treatment, and casting operations cannot be ignored because of the adoption of the filtration process. It is also necessary to prevent the recontamination of the filtered clean aluminum liquid.

The installation of alumina ceramic foam filter board, in general, need to pay attention to the following aspects:

1. Correct selection of alumina ceramic foam filter plate:

The size of the filter plate and the selection of the number of holes must take into account the flow rate range of the specific casting type, the maximum level of the metal during filtration, the total filtration volume, and the cleanliness of the original aluminum liquid.

2. The pretreatment of melt filtration cannot be ignored:

Such as the normal slagging and cleaning of aluminum melting furnace and holding furnace; refining in the furnace, etc. Especially the on-line degassing device is still necessary because it can not only reduce the hydrogen content of the melt, but also remove some non-metallic inclusions.

3. The filter plate must be compatible with the square fire-resistant filter box:

The two are adapted to facilitate sealing, which not only prevents the metal from flowing into the casting box from the gap without being filtered, but also prevents the foam filter plate from being too light and floating in the aluminum water and failing.

4. Preheat before use:

Preheat to remove water and facilitate initial instant filtration. Preheating can be implemented by electric or gas heating. Under normal circumstances, it takes about 15 minutes.

5. During the normal filtration process, there is no need to slag and avoid knocking and vibrating the filter plate. At the same time, the launder should be filled with molten aluminum to avoid too much worry about the molten aluminum.

6. After casting, drain the metal on the launder and filter plate. There is a kind of vibrator abroad, which is placed on the filter plate and vibrates for one minute, which can shake off about 75% of the remaining liquid metal from the filter plate.

7. Finally, clean up the surrounding area and take out the filter plate after solidification.

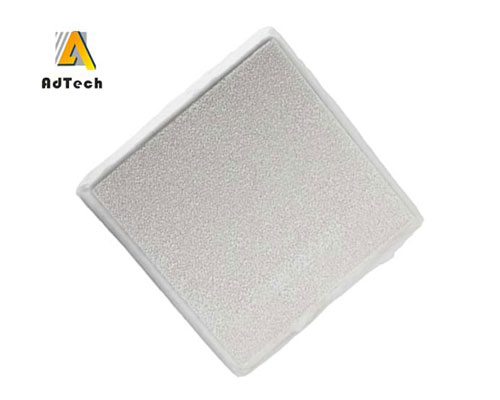

The alumina ceramic filter has excellent thermal shock resistance, strength, high porosity and specific surface area, can filter and adsorb the smallest possible inclusions in the molten metal, and use its unique rectification effect to obtain Smooth and fast laminar flow prevents air bubbles from entering, and is suitable for the requirements of different refractoriness and pouring speed in the foundry industry. It can significantly improve the quality of castings, which is conducive to cutting, thereby reducing tool wear and manufacturing costs.