A finer grain size promotes improved casting soundness by minimizing shrinkage, hot cracking, and hydrogen porosity. Under normal solidification conditions spanning the full range of commercial casting processes, aluminum alloys without grain refinement exhibit coarse columnar and/or coarse equiaxed structures.

A fine grain structure also minimizes the effects on castability and properties associated with the size and distribution of normally occurring intermetallics. Large, insoluble intermetallic particles that are present or form in the temperature range between liquidus and solidus reduce feeding. A fine grain size promotes the formation of finer, more evenly distributed intermetallic particles with corresponding improvements in feeding characteristics. Because most of these more brittle phases precipitate late in the solidification process, their preferential formation at grain boundaries also profoundly affects tear resistance and mechanical properties in coarse-grain structures.

In addition to oxides, a number of additional compounds can be considered inclusions in cast structures. All aluminum contains aluminum carbide (Al4C3) formed during reduction. Borides may also be present. By agglomeration, borides can assume sufficient size to represent a significant factor in the metal structure, with especially adverse effects in machining.

Effects of Inclusions

Under all conditions, inclusions whether in film or particle form are damaging to mechanical properties. The gross effect of inclusions is to reduce the effective cross section of metal under load. The more devastating effect on properties is that of stress concentration when inclusions appear at or near the surface of parts or specimens. Fatigue performance is reduced under the latter condition by the notch effect. Ultimate and yield strengths are typically lower, and ductility may be substantially reduced when inclusions are present.

Hard particle inclusions are frequently found in association with film-type oxides. Borides, carbides, oxides, and nonmetallic particles in the melt are scavenged and then concentrated in localized regions within the cast structure.

Grain Structure

A fine, equiaxed grain structure is normally desired in aluminum castings. The type and size of grains formed are determined by alloy composition, solidification rate, and the addition of master alloys (grain refiners) containing intermetallic phase particles, which provide sites for heterogeneous grain nucleation.

Porosity, if present, is of smaller discrete void size in fine-grain parts. The size of interdendritic shrinkage voids is directly influenced by grain size.

The finer distribution of soluble intermetallics throughout grain-refined castings results in faster and more complete response to thermal treatment. More consistent mechanical properties can be expected following thermal treatment.

Grain Refinement

All aluminum alloys can be made to solidify with a fully equiaxed, fine grain structure refinement through the use of suitable grain-refining additions. The most widely used grain refiners are master alloys of titanium additive, or of titanium and boron, in aluminum. Aluminum-titanium refiners generally contain from 3 to 10% Ti. The same range of titanium concentrations is used in Al-Ti-B refiners with boron contents from 0.2 to 1% and titanium-to-boron ratios ranging from about 5 to 50. Although grain refiners of these types can be considered conventional hardeners or master alloys, they differ from master alloys added to the melt for alloying purposes alone.

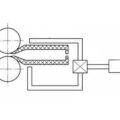

To be effective, grain refiners must introduce controlled, predictable, and operative quantities of aluminides (and borides) in the correct form, size, and distribution for grain nucleation. Wrought refiner in rod form, developed for the continuous treatment of aluminum in primary operations, is available in sheared lengths for foundry use.