The function of the aluminum liquid control system is to stabilize the liquid level of the front tank, keep the supply of liquid metal sufficient and stable, and ensure the continuity of casting and rolling.

Aluminum Liquid Control System

The lever flow controller uses the working principle of the lever to realize the smooth control of the liquid level of the controller box. Horizontal flow control is suitable for continuous casting and rolling with the same horizontal flow. The vertical flow control is suitable for the flow supply method where there is a gap between the supply flow channel and the front box flow channel. The principle is that the liquid level of the front tank flow channel is raised and lowered to drive the float to rise and fall, and then the connecting rod acts on the plug to achieve a stable supply of metal liquid.

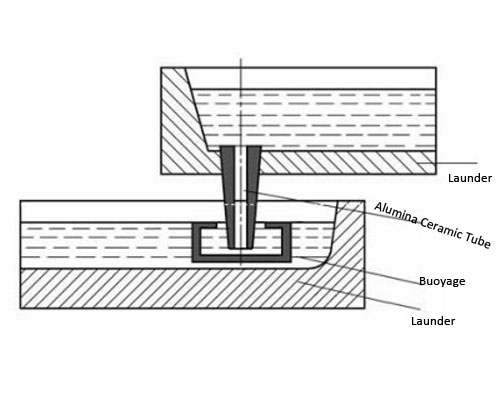

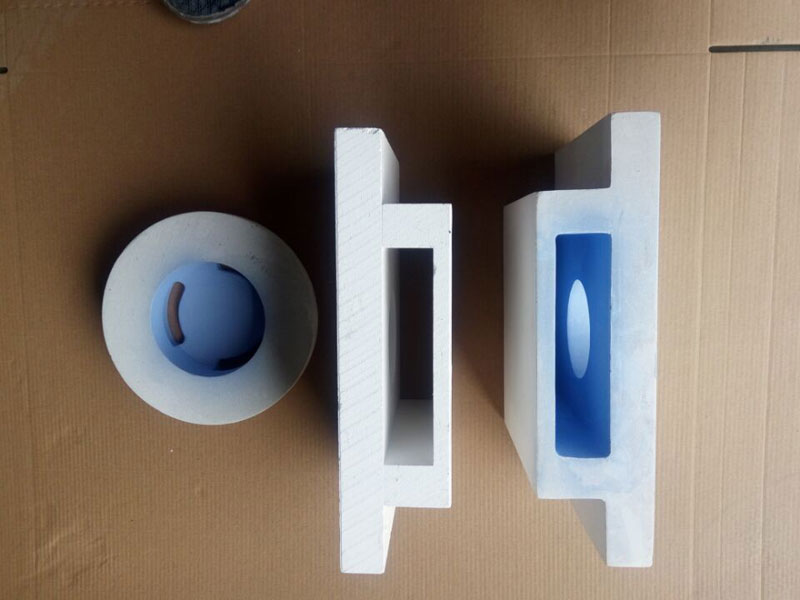

The float flow control device, according to the principle of liquid buoyancy, drives the float to move up and down through the rise and fall of the metal liquid level in the front tank flow tank, and controls the size of the gap between the float and the flow tube to achieve the stability of the control liquid level. It is better to use refractory materials with lower density to improve the sensitivity.

A page sensor is installed above the front tank flow slot. The measurement sensor probe does not come into contact with the liquid metal. The reference frame is the upper surface of the liquid metal. Through the sensor parallel signal to the controller, the controller compares the liquid level reflected by the signal with the set point, and then sends the signal to the governor. The motor of the governor regulates the rise and fall of the plug to effectively control the flow of liquid metal.