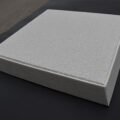

40PPI Ceramic Foam Filter allows the molten aluminum metal in the aluminum melting and casting workshop to flow smoothly into the casting surface, forming with the best purity and arrangement. Because the alumina filter can withstand a wide range of high temperatures, it can be used for casting of different metals, so that it has a wide range of uses. 40PPI ceramic foam filter provides high-quality molten metal for aluminum metal casting plants. The purpose of filtering molten metal is to remove impurities and keep the casting away from the air. When a ceramic foam filter is used, the porosity in the cast material decreases.

In aluminum melting and casting workshops, it has become common to install Foundry Ceramic Filters to remove molten aluminum impurities. This type of filter must be selected according to its physical and chemical properties.

Various metal foundries are introducing ceramic foam filters to introduce the best quality casting materials into their product lines. This can filter out impurities, but has high-quality compression and durability, resulting in the finest cast metal.

40PPI ceramic foam filter (CFF) has been widely used for filtering impurities out of molten aluminium in cast houses and foundry. Filtration is a necessary step to optimize metal quality and downstream finished products. Inclusions can originate from a variety of sources during the production process, including surface oxide films, eroded furnace refractories and insoluble impurities like carbides.

With the demand for high quality aluminium products increasing, filtration has proved an optimum method for improving metal quality. Technical advances in CFF, such as fine pore filters and improved filtration systems better suited to the stringent operating conditions of the casthouse have offered an efficient method of removing inclusions from liquid aluminium in a wide range of critical applications.

Ceramic foam filters offer a simple, reliable and costeffective method to remove inclusions. Filtering with CFF is a supplement to metal treatment within the furnace, such as fluxing and degassing or inline filtration.